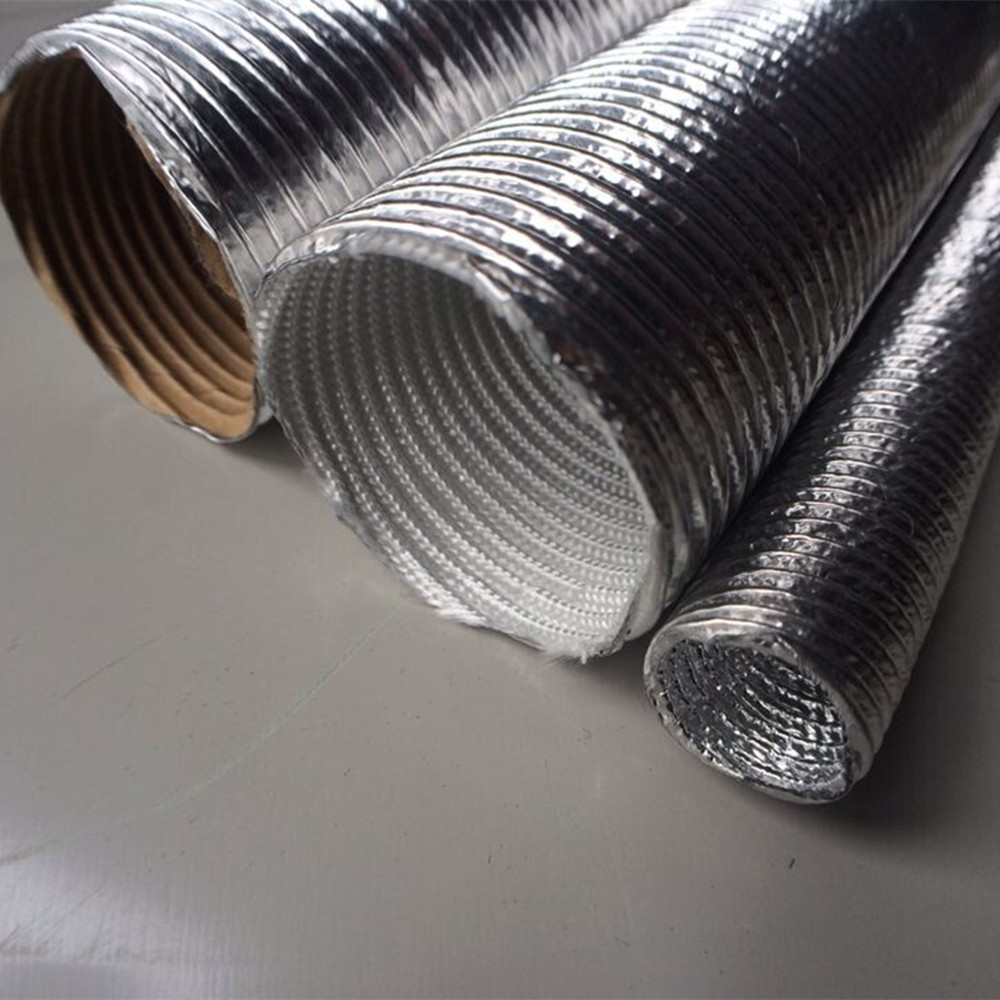

ШӘШ№ШӘШЁШұ Ш§Щ„ЩӮЩҶШ§Ш© Ш§Щ„Щ…Щ…ЩҲШ¬Ш© Щ…ЩҶ ШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ… Щ…ЩғЩҲЩҶЩӢШ§ ШЈШіШ§ШіЩҠЩӢШ§ Щ„ШӯЩ…Ш§ЩҠШ© Ш§Щ„Ш®ШұШ§Ш·ЩҠЩ… Ш§Щ„Щ…Ш·Ш§Ш·ЩҠШ©ШҢ ЩҲШЈШӯШІЩ…Ш© Ш§Щ„ШЈШіЩ„Ш§ЩғШҢ ЩҲШ§Щ„ЩғШ§ШЁЩ„Ш§ШӘ ЩҒЩҠ Ш§Щ„ШЁЩҠШҰШ§ШӘ Ш°Ш§ШӘ ШҜШұШ¬Ш§ШӘ Ш§Щ„ШӯШұШ§ШұШ© Ш§Щ„Ш№Ш§Щ„ЩҠШ©. Щ…ШөЩҶЩҲШ№Ш© Щ…ЩҶ Ш«Щ„Ш§Ш« Ш·ШЁЩӮШ§ШӘ - ШӘШ¬ШҜЩҠЩ„ Ш®ЩҠЩҲШ· Ш§Щ„ШЈЩ„ЩҠШ§ЩҒ Ш§Щ„ШІШ¬Ш§Ш¬ЩҠШ© ЩғШ·ШЁЩӮШ© ЩҲШіШ·ЩүШҢ ЩҲШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ… Щ…ЩҶ Ш§Щ„ШҜШ§Ш®Щ„ ЩҲШ§Щ„Ш®Ш§ШұШ¬ - ШӘЩҲЩҒШұ ЩҮШ°ЩҮ Ш§Щ„ЩӮЩҶШ§Ш© Щ…ШІШ§ЩҠШ§ ЩҒШұЩҠШҜШ©:

ЩҠЩҲЩҒШұ Ш§Щ„ШӘШөЩ…ЩҠЩ… Ш§Щ„Щ…ШӘШ®ШөШө Щ„Щ„ЩӮЩҶШ§Ш© Ш§Щ„Щ…Щ…ЩҲШ¬Ш© Щ…ЩҶ ШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ… ШӯЩ…Ш§ЩҠШ© Щ…Щ…ШӘШ§ШІШ© Щ„Щ„ШӯШұШ§ШұШ© Ш№Щ„Щү Ш§Щ„Щ…ШҜЩү Ш§Щ„Ш·ЩҲЩҠЩ„. ШӘШ№ЩғШі ШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ… Ш§Щ„ШӯШұШ§ШұШ© ШЁШҙЩғЩ„ ЩҒШ№Ш§Щ„ ШЁШ№ЩҠШҜЩӢШ§ Ш№ЩҶ Ш§Щ„Щ…ЩғЩҲЩҶШ§ШӘ Ш§Щ„ШӯШіШ§ШіШ©ШҢ Щ…Щ…Ш§ ЩҠЩ…ЩҶШ№ Ш§Щ„ШӘШҜЩҮЩҲШұ Ш§Щ„ШӯШұШ§ШұЩҠ Щ„Щ„Ш®ШұШ§Ш·ЩҠЩ… ЩҲШ§Щ„ЩғШ§ШЁЩ„Ш§ШӘ Ш§Щ„Щ…Ш·Ш§Ш·ЩҠШ© ЩҒЩҠ Ш§Щ„Щ…ЩҶШ§Ш·ЩӮ Ш°Ш§ШӘ ШҜШұШ¬Ш© Ш§Щ„ШӯШұШ§ШұШ© Ш§Щ„Ш№Ш§Щ„ЩҠШ© Щ…Ш«Щ„ ШәШұЩҒ Ш§Щ„Щ…ШӯШұЩғШ§ШӘ.

ШҘЩҶ Ш§Щ„Ш¬Щ…Ш№ ШЁЩҠЩҶ ШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ… ЩҲШ®ЩҠЩҲШ· Ш§Щ„ШЈЩ„ЩҠШ§ЩҒ Ш§Щ„ШІШ¬Ш§Ш¬ЩҠШ© ЩҠШ®Щ„ЩӮ ШӯШ§Ш¬ШІЩӢШ§ ЩӮЩҲЩҠЩӢШ§ ЩҠЩӮШ§ЩҲЩ… Ш§Щ„Ш¶ШәШ· Ш§Щ„Ш¬ШіШҜЩҠ ЩҲШ§Щ„ШӘШўЩғЩ„. ШӘШ¶Щ…ЩҶ ЩҮШ°ЩҮ Ш§Щ„Щ…ШӘШ§ЩҶШ© ШЈЩҶ Ш§Щ„ЩӮЩҶШ§Ш© ШӘШӯЩ…ЩҠ Ш§Щ„Щ…ЩғЩҲЩҶШ§ШӘ Ш§Щ„ШӯЩҠЩҲЩҠШ© Щ…ЩҶ Ш§Щ„ШӘШўЩғЩ„ШҢ Щ…Щ…Ш§ ЩҠШІЩҠШҜ Щ…ЩҶ Ш№Щ…ШұЩҮШ§ Ш§Щ„Ш§ЩҒШӘШұШ§Ш¶ЩҠ ЩҲЩ…ЩҲШ«ЩҲЩӮЩҠШӘЩҮШ§.

Щ…Ш№ ЩҶШ·Ш§ЩӮ ШҜШұШ¬Ш© ШӯШұШ§ШұШ© Ш§Щ„Ш№Щ…Щ„ Щ…ЩҶ -50 ШҜШұШ¬Ш© Щ…ШҰЩҲЩҠШ© ШҘЩ„Щү +200 ШҜШұШ¬Ш© Щ…ШҰЩҲЩҠШ©ШҢ ЩҒШҘЩҶ ЩҮШ°ЩҮ Ш§Щ„ЩӮЩҶШ§Ш© Щ…ЩҶШ§ШіШЁШ© Щ„Щ…Ш®ШӘЩ„ЩҒ Ш§Щ„ШӘШ·ШЁЩҠЩӮШ§ШӘ Ш№ШЁШұ Ш§Щ„Ш№ШҜЩҠШҜ Щ…ЩҶ Ш§Щ„ШөЩҶШ§Ш№Ш§ШӘ. ШҘЩҶ ЩӮШҜШұШӘЩҮШ§ Ш№Щ„Щү Ш§Щ„ШЈШҜШ§ШЎ ЩҒЩҠ Ш§Щ„ШёШұЩҲЩҒ Ш§Щ„ЩӮШ§ШіЩҠШ© ШӘШ¬Ш№Щ„ЩҮШ§ Щ…Ш«Ш§Щ„ЩҠШ© Щ„ШӘШ·ШЁЩҠЩӮШ§ШӘ Ш§Щ„ШіЩҠШ§ШұШ§ШӘ ЩҲШ§Щ„ШіЩғЩғ Ш§Щ„ШӯШҜЩҠШҜЩҠШ© ЩҲШ§Щ„Щ…ШӯШұЩғШ§ШӘ ЩҲШ§Щ„Щ…ШӯЩҲЩ„Ш§ШӘ.

ЩҠШӘЩҠШӯ Ш§Щ„ШӘШөЩ…ЩҠЩ… Ш§Щ„Щ…Щ…ЩҲШ¬ Ш§Щ„Щ…ШұЩҲЩҶШ© ЩҲШіЩҮЩҲЩ„Ш© Ш§Щ„ШӘШұЩғЩҠШЁ ЩҒЩҠ Ш§Щ„Щ…ШіШ§ШӯШ§ШӘ Ш§Щ„Ш¶ЩҠЩӮШ©. ЩҠЩ…ЩғЩҶ ШӘЩҲШ¬ЩҠЩҮ ЩҮШ°ЩҮ Ш§Щ„ЩӮЩҶШ§Ш© Ш®ЩҒЩҠЩҒШ© Ш§Щ„ЩҲШІЩҶ ШЁШіЩҮЩҲЩ„Ш© ШӯЩҲЩ„ Ш§Щ„Ш№ЩҲШ§ШҰЩӮШҢ Щ…Щ…Ш§ ЩҠЩҲЩҒШұ ШӯЩ…Ш§ЩҠШ© ЩҒШ№Ш§Щ„Ш© ШҜЩҲЩҶ ШҘШ¶Ш§ЩҒШ© ШӯШ¬Щ… ЩғШЁЩҠШұ ШҘЩ„Щү Ш§Щ„ЩҶШёШ§Щ….

ШҘЩҶ Ш§Щ„ШЈЩҶШ§ШЁЩҠШЁ Ш§Щ„Щ…Щ…ЩҲШ¬Ш© Ш§Щ„Щ…ШөЩҶЩҲШ№Ш© Щ…ЩҶ ШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ… Щ…ЩӮШ§ЩҲЩ…Ш© Щ„Щ„Щ…ЩҲШ§ШҜ Ш§Щ„ЩғЩҠЩ…ЩҠШ§ШҰЩҠШ© Ш§Щ„Щ…Ш®ШӘЩ„ЩҒШ©ШҢ Щ…Щ…Ш§ ЩҠШ¬Ш№Щ„ЩҮШ§ Щ…ЩҶШ§ШіШЁШ© Щ„Щ„ШЁЩҠШҰШ§ШӘ Ш§Щ„ШӘЩҠ ЩҠЩғЩҲЩҶ ЩҒЩҠЩҮШ§ Ш§Щ„ШӘШ№ШұШ¶ Щ„Щ„ШІЩҠЩҲШӘШҢ Ш§Щ„ЩҲЩӮЩҲШҜШҢ ЩҲШәЩҠШұЩҮШ§ Щ…ЩҶ Ш§Щ„Щ…ЩҲШ§ШҜ Ш§Щ„ЩӮШ§ШіЩҠШ© ШЈЩ…ШұЩӢШ§ ШҙШ§ШҰШ№ЩӢШ§. ШӘШ№Щ…Щ„ ЩҮШ°ЩҮ Ш§Щ„Щ…ЩҠШІШ© Ш№Щ„Щү ШӘШ№ШІЩҠШІ ШіЩ„Ш§Щ…Ш© ЩҲШ·ЩҲЩ„ Ш№Щ…Шұ Ш§Щ„Ш®ШұШ§Ш·ЩҠЩ… ЩҲШ§Щ„ЩғШ§ШЁЩ„Ш§ШӘ Ш§Щ„ШӘЩҠ ШӘШӯЩ…ЩҠЩҮШ§.

ЩҠЩ…ЩғЩҶ ШЈЩҶ ЩҠШӨШҜЩҠ Ш§Щ„Ш§ШіШӘШ«Щ…Ш§Шұ ЩҒЩҠ Ш§Щ„ЩӮЩҶШ§Ш© Ш§Щ„Щ…Щ…ЩҲШ¬Ш© ШЁШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ… ШҘЩ„Щү ШӘЩҲЩҒЩҠШұ ЩғШЁЩҠШұ ЩҒЩҠ Ш§Щ„ШӘЩғШ§Щ„ЩҠЩҒ ШЁЩ…ШұЩҲШұ Ш§Щ„ЩҲЩӮШӘ. Щ…ЩҶ Ш®Щ„Ш§Щ„ Щ…ЩҶШ№ Ш§Щ„ШЈШ№Ш·Ш§Щ„ Ш§Щ„Щ…ШұШӘШЁШ·Ш© ШЁШ§Щ„ШӯШұШ§ШұШ© ЩҲШ§Щ„ШЈШ¶ШұШ§Шұ Ш§Щ„Щ…ЩҠЩғШ§ЩҶЩҠЩғЩҠШ©ШҢ ШӘЩӮЩ„Щ„ ЩҮШ°ЩҮ Ш§Щ„ЩӮЩҶШ§Ш© Щ…ЩҶ Ш§Щ„ШӯШ§Ш¬Ш© ШҘЩ„Щү Ш§Щ„Ш§ШіШӘШЁШҜШ§Щ„ ЩҲШ§Щ„ШөЩҠШ§ЩҶШ© Ш§Щ„Щ…ШӘЩғШұШұШ© Щ„Щ„Ш®ШұШ§Ш·ЩҠЩ… ЩҲШ§Щ„ЩғШ§ШЁЩ„Ш§ШӘ.

ЩҠШӘЩ… Ш§ШіШӘШ®ШҜШ§Щ… ЩҮШ°ЩҮ Ш§Щ„ЩӮЩҶШ§Ш© Ш№Щ„Щү ЩҶШ·Ш§ЩӮ ЩҲШ§ШіШ№ ЩҒЩҠ Ш§Щ„Ш№ШҜЩҠШҜ Щ…ЩҶ Ш§Щ„ШөЩҶШ§Ш№Ш§ШӘШҢ ШЁЩ…Ш§ ЩҒЩҠ Ш°Щ„Щғ:

ЩӮЩҶШ§Ш© Щ…Щ…ЩҲШ¬Ш© Щ…ЩҶ ШұЩӮШ§ШҰЩӮ Ш§Щ„ШЈЩ„ЩҲЩ…ЩҶЩҠЩҲЩ…ЩҮЩҲ Ш§Щ„ШӯЩ„ Ш§Щ„ШЈЩ…Ш«Щ„ Щ„ШӯЩ…Ш§ЩҠШ© Ш§Щ„Ш®ШұШ§Ш·ЩҠЩ… Ш§Щ„Щ…Ш·Ш§Ш·ЩҠШ©ШҢ ЩҲШЈШӯШІЩ…Ш© Ш§Щ„ШЈШіЩ„Ш§ЩғШҢ ЩҲШ§Щ„ЩғШ§ШЁЩ„Ш§ШӘ Щ…ЩҶ ШҜШұШ¬Ш§ШӘ Ш§Щ„ШӯШұШ§ШұШ© Ш§Щ„Щ…ШұШӘЩҒШ№Ш© ЩҲШ§Щ„ШЈШ¶ШұШ§Шұ Ш§Щ„Щ…ЩҠЩғШ§ЩҶЩҠЩғЩҠШ©. ШҘЩҶ ШЁЩҶЩҠШӘЩҮ Ш§Щ„ЩҒШұЩҠШҜШ©ШҢ ШҘЩ„Щү Ш¬Ш§ЩҶШЁ Щ…Ш¬Щ…ЩҲШ№Ш© ЩҲШ§ШіШ№Ш© Щ…ЩҶ Ш§Щ„ШӘШ·ШЁЩҠЩӮШ§ШӘ ЩҲЩ…ШұЩҲЩҶШ© ШҜШұШ¬Ш§ШӘ Ш§Щ„ШӯШұШ§ШұШ©ШҢ ШӘШ¬Ш№Щ„ЩҮ Ш®ЩҠШ§ШұЩӢШ§ Щ„Ш§ ШәЩҶЩү Ш№ЩҶЩҮ Щ„Щ„ШөЩҶШ§Ш№Ш§ШӘ Ш§Щ„ШӘЩҠ ШӘШӘШ·Щ„ШЁ ШҘШҜШ§ШұШ© ЩҲШӯЩ…Ш§ЩҠШ© Щ…ЩҲШ«ЩҲЩӮШ© Щ„Щ„ШӯШұШ§ШұШ©.