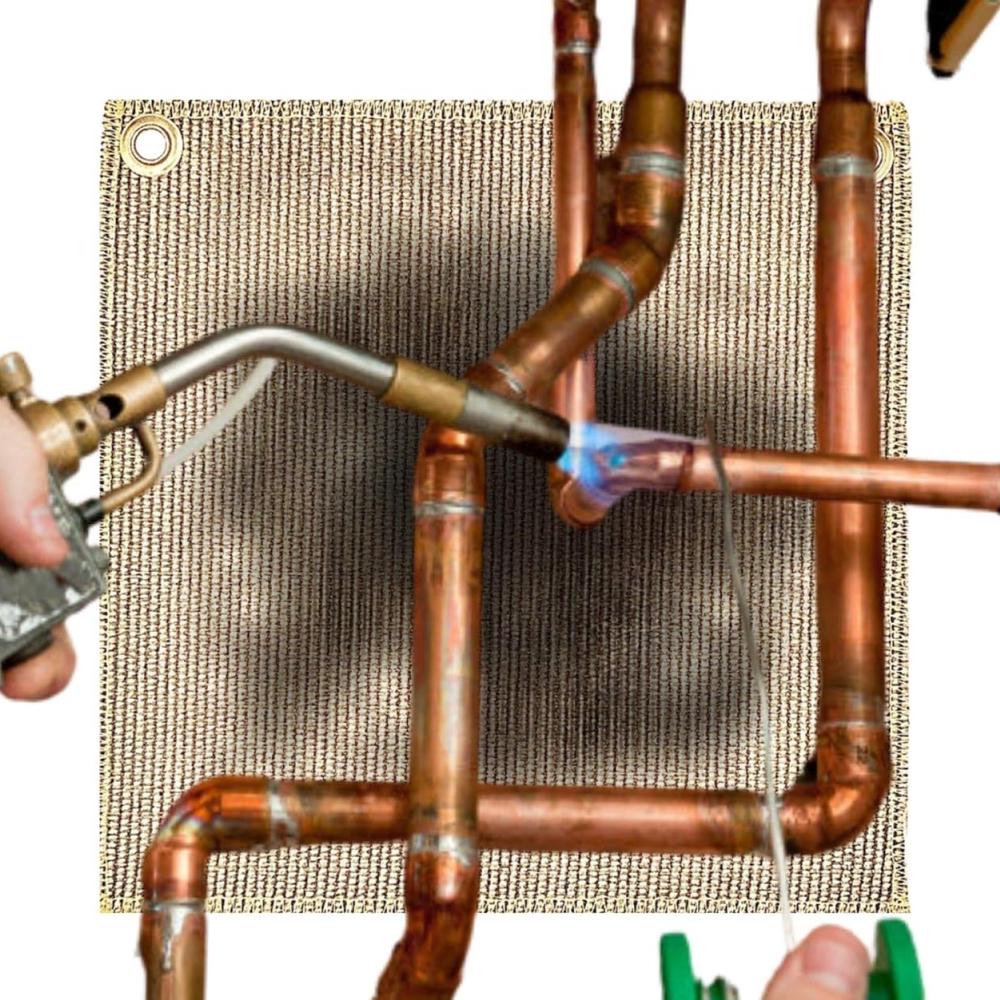

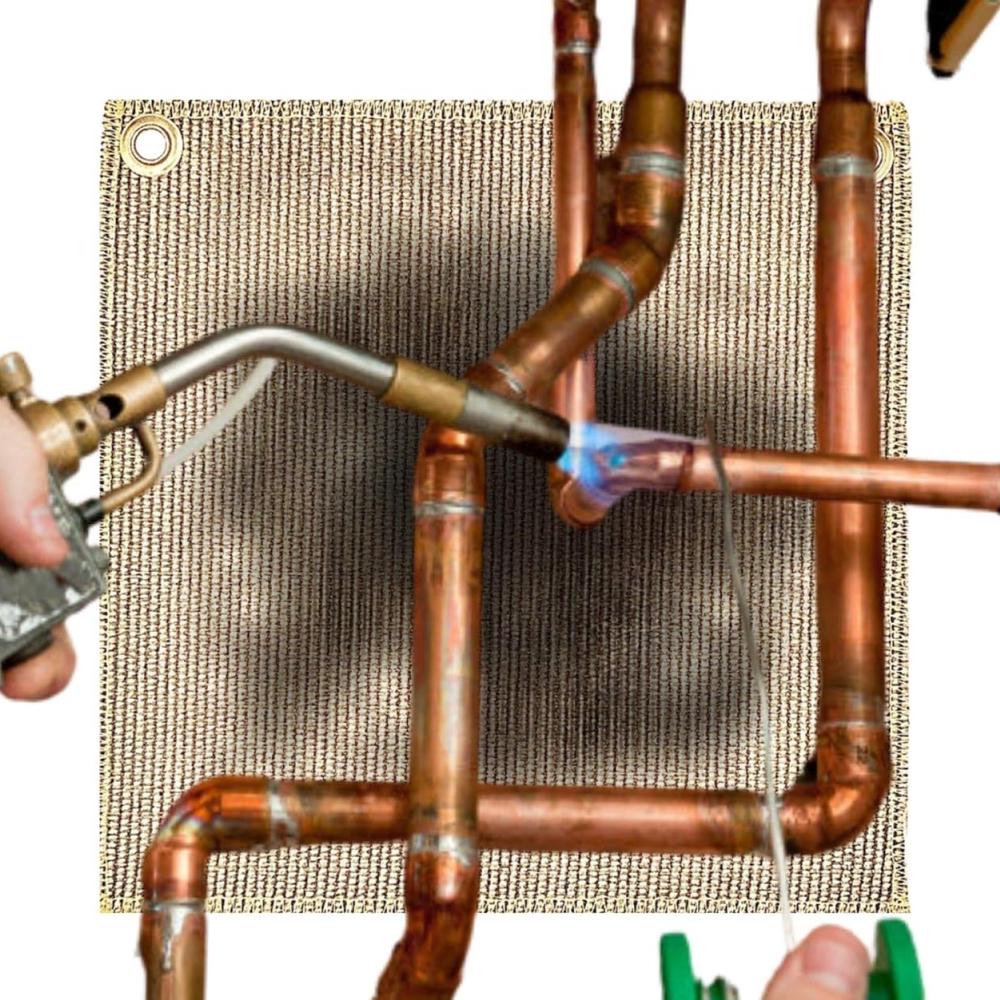

فهم الدروع الحرارية للحام: الغرض والأداء والتطبيقات العملية

يعد درع اللحام الحراري أداة أساسية تستخدم في مختلف الصناعات لحماية المكونات والأسطح من الحرارة الشديدة المتولدة أثناء عمليات اللحام. والغرض منه هو ضمان الدقة والسلامة من خلال التخفيف من مخاطر الأضرار الناجمة عن الحرارة، مما يجعله أصلاً لا يقدر بثمن في مجال الإلكترونيات، وصناعة المجوهرات، وغيرها من المهام القائمة على الدقة.

ما هو الدرع الحراري للحام؟

عادةً ما يكون درع اللحام الحراري عبارة عن حاجز مقاوم للحرارة مصمم لحماية المناطق الحساسة من درجات الحرارة المرتفعة الناتجة أثناء اللحام. مصنوعة من مواد مثل السيليكون أو الألياف الزجاجية أو السبائك المعدنية ذات خصائص العزل الحراري الممتازة، وتأتي هذه الدروع في أشكال مختلفة، بما في ذلك الوسائد والحصائر والشاشات.

ميزات الأداء الرئيسية:

-

مقاومة الحرارة: تم تصميم الدروع الحرارية للحام لتحمل درجات حرارة تتجاوز في كثير من الأحيان 300 درجة مئوية (572 درجة فهرنهايت)، مما يضمن حماية المكونات المحيطة من أضرار الحرارة.

-

العزل الحراري: توفر عزلاً فعالاً، حيث تمنع انتقال الحرارة إلى الأجزاء الحساسة القريبة، وبالتالي تقلل من خطر التدهور الحراري.

-

المتانة: تم تصميم هذه الدروع، المصنوعة من مواد قوية، لاستخدامها بشكل متكرر في البيئات ذات درجات الحرارة العالية دون أن تفقد فعاليتها.

-

سهولة الاستخدام: تم تصميم العديد من الواقيات الحرارية لسهولة وضعها وإزالتها، مما يسمح للمستخدمين بدمجها بسلاسة في سير العمل.

تطبيقات وسيناريوهات عملية:

-

صناعة الإلكترونيات:

-

السيناريو: في تجميع الإلكترونيات، يتم استخدام الدروع الحرارية للحام لحماية المكونات الإلكترونية الحساسة من الحرارة أثناء لحام التوصيلات على لوحات الدوائر المطبوعة (PCBs).

-

مشاركة المستخدم: "لقد أدى استخدام الواقيات الحرارية أثناء عملية اللحام إلى تغيير قواعد اللعبة بالنسبة لنا. فهي تمنع تلف المكونات الحساسة وتضمن الحفاظ على معايير الجودة العالية دون القلق بشأن ارتفاع درجة الحرارة."

-

صنع المجوهرات:

-

السيناريو: يستخدم الجواهريون الدروع الحرارية لحماية الأحجار الكريمة والإعدادات المعدنية الدقيقة أثناء لحام المفاصل أو الإصلاحات.

-

مشاركة المستخدم: "في صناعة المجوهرات، تعد دقة الدروع الحرارية أمرًا بالغ الأهمية. فهي تسمح لي بالعمل على تصميمات معقدة دون المخاطرة بتلف الأحجار الكريمة بسبب الحرارة، مما يضمن الجودة والسلامة."

-

إصلاح السيارات:

-

السيناريو: أثناء إصلاحات السيارات، يتم استخدام الدروع الحرارية لحماية المكونات البلاستيكية أو الإلكترونية القريبة من الحرارة المتولدة أثناء عمليات اللحام أو اللحام.

-

مشاركة المستخدم: "في محلات تصليح السيارات، لا غنى عن الدروع الحرارية. فهي تساعدنا على تجنب ذوبان الأجزاء المجاورة أو تشويهها، مما يجعل الإصلاحات أكثر موثوقية وأقل استهلاكًا للوقت."

-

مشاريع DIY:

-

السيناريو:يستخدم الهواة وعشاق الأعمال اليدوية الدروع الحرارية لتجنب تلف المواد المحيطة أثناء العمل في مشاريع اللحام، مثل تجميع الأجهزة الإلكترونية المخصصة أو الصناعة اليدوية.

-

مشاركة المستخدم: "بالنسبة لمشاريع الإلكترونيات التي تصنعها بنفسك، يعد وجود درع حراري جيد أمرًا ضروريًا. فهو يساعد في الحفاظ على نظافة منطقة العمل ويمنع حدوث تلف عرضي للأجزاء الأخرى، مما يجعل العملية برمتها أكثر سلاسة."

الخلاصة

الدروع الحرارية للحام هي أدوات حيوية في مختلف الصناعات، حيث توفر حماية حاسمة ضد الأضرار الناجمة عن الحرارة. العزل الحراري الفعال والمتانة وسهولة الاستخدام يجعلها لا غنى عنها في الحفاظ على الدقة والسلامة في مهام اللحام. سواء كنت تعمل في تصنيع الإلكترونيات، أو صناعة المجوهرات، أو إصلاح السيارات، أو تشارك في مشاريع DIY، فإن دمج درع حراري عالي الجودة في عمليتك سيعزز جودة عملك وكفاءته.