غلاف الحماية من الانفجار للخراطيم الهيدروليكية هو نوع من الغطاء الواقي المصمم لمنع الخراطيم الهيدروليكية من الانفجار أو الفشل تحت الضغط العالي. تُستخدم الخراطيم الهيدروليكية لنقل السوائل في مختلف الآلات والمعدات، وتعمل تحت ضغط كبير، مما قد يؤدي إلى التآكل أو التآكل أو حتى الفشل الكارثي إذا لم يتم حمايتها بشكل صحيح.

وفيما يلي نظرة فاحصة على الأكمام الحماية من الانفجار:

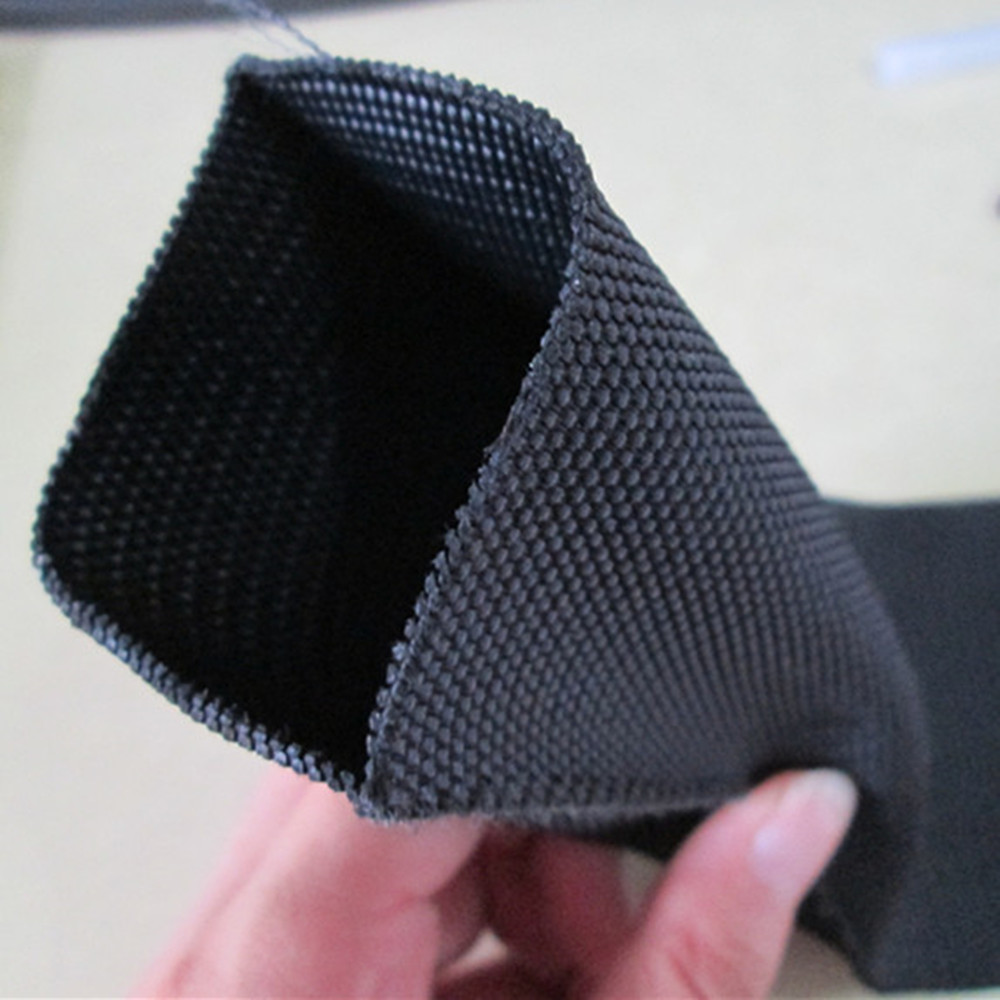

المواد والتصميم: يتم تصنيع الغلاف عادةً من مواد عالية القوة مثل الفولاذ المضفر أو الكيفلار أو البوليمرات المتخصصة. توفر هذه المواد مستوى عالٍ من المقاومة للضغط والتآكل والتأثير.

الوظيفة: تتمثل الوظيفة الأساسية للغطاء في احتواء الفوضى والأضرار المحتملة والتحكم فيها في حالة انفجار الخرطوم. فهو يساعد على منع إطلاق السوائل ذات الضغط العالي، والتي قد تسبب ضررًا أو تلفًا للمكونات أو الآلات أو الموظفين القريبين.

التثبيت: عادة ما يتم تركيب جلبة الحماية من الانفجار فوق الخراطيم الهيدروليكية. يمكن تركيبه فوق الخراطيم الموجودة أو استخدامه كجزء من عملية تجميع الخرطوم. تم تصميم بعض خيارات الأكمام بحيث يتم قصها حسب الحجم ثم تثبيتها في مكانها باستخدام المشابك أو الروابط.

الفوائد:

التطبيقات: يتم استخدام غلاف الحماية من الانفجار بشكل شائع في الصناعات التي تنتشر فيها الأنظمة الهيدروليكية، مثل التصنيع والبناء والطيران والسيارات.

بشكل عام، يعد دمج جلب الحماية من الانفجار في الأنظمة الهيدروليكية بمثابة إجراء أمان استباقي يعزز موثوقية وسلامة العمليات الهيدروليكية.