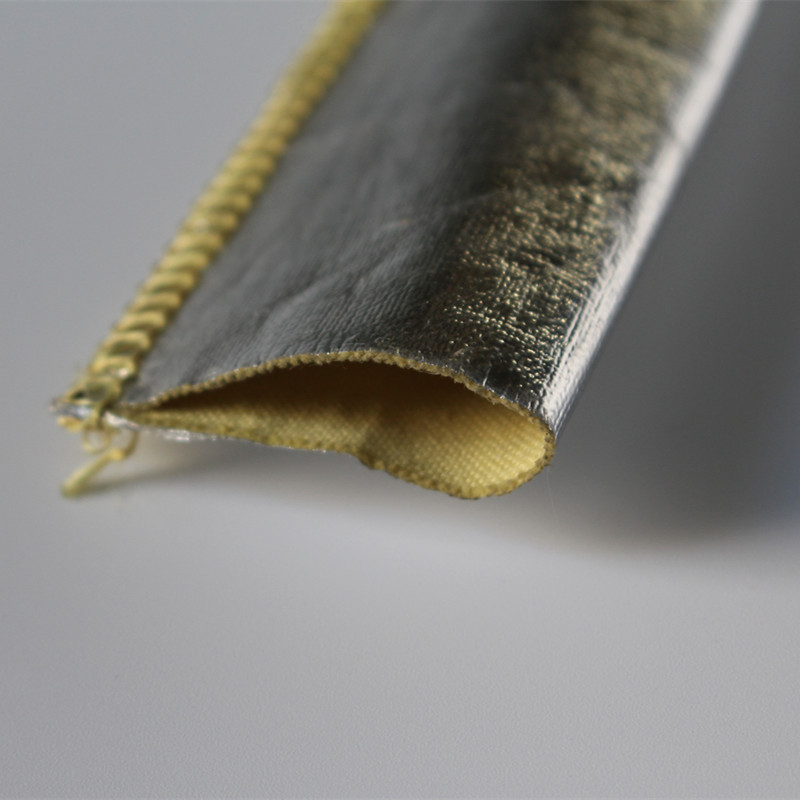

تم تصميم غلاف الكيفلار الحراري المصنوع من الألومنيوم لتوفير حماية حرارية فائقة ومتانة، وهو مصمم لتحمل درجات الحرارة القصوى والظروف القاسية. يتكون هذا الغلاف من قاعدة كيفلار عالية القوة وطبقة خارجية من الألومنيوم، ويعكس الحرارة المشعة بينما يوفر مقاومة ممتازة للتآكل والقطع. يتم استخدامه على نطاق واسع في تطبيقات السيارات والفضاء والتطبيقات الصناعية لحماية الخراطيم والأسلاك والمكونات المعرضة للحرارة العالية.

ميزات الأداء الرئيسية

تطبيقات العالم الحقيقي

في صناعة السيارات، تُستخدم غالبًا أغطية الكيفلار الحرارية المصنوعة من الألومنيوم لحماية خطوط الوقود والأسلاك والخراطيم في المركبات عالية الأداء. قال أحد فنيي سيارات السباق، "لقد كان استخدام غلاف الكيفلار الحراري المصنوع من الألومنيوم بمثابة تغيير في قواعد اللعبة بالنسبة لنا. فهو يحافظ على خطوط الوقود لدينا آمنة من أضرار الحرارة، مما يضمن أداءً ثابتًا على المسار."

في الفضاء، يعد هذا الغلاف ضروريًا لعزل المكونات في محركات الطائرات وأنظمة العادم. قال أحد مهندسي الفضاء الجوي: "نحن نعتمد على هذا الغلاف لحماية الأسلاك الحساسة في المناطق ذات درجات الحرارة المرتفعة. فهو يقلل بشكل كبير من خطر الأعطال الناجمة عن التعرض للحرارة."

وفي التطبيقات الصناعية، يتم تطبيقه على عزل الأنابيب والصمامات والمعدات التي تعمل بالقرب من الأفران أو في الظروف القاسية. وأشار مدير المنشأة، "لقد أدى غلاف الكيفلار الحراري إلى تحسين عمر أجهزتنا بشكل كبير. فهو يتحمل الحرارة والتآكل، مما يقلل من تكاليف الصيانة والاستبدال."

الفوائد

الخلاصة

الكم الحراري المصنوع من الكيفلار بالألمنيومهو الحل الأمثل لأي شخص يبحث عن حماية حرارية استثنائية في البيئات شديدة الحرارة. إن مزيجها من مقاومة الحرارة والمتانة والمرونة خفيفة الوزن يجعلها لا غنى عنها في تطبيقات السيارات والفضاء والتطبيقات الصناعية. سواء كان حماية خطوط الوقود أو عزل الأسلاك الحساسة، فإن هذا الغلاف يوفر أداءً وأمانًا لا مثيل لهما.